SPO (Plan 53C)

SPO (Plan 53C)

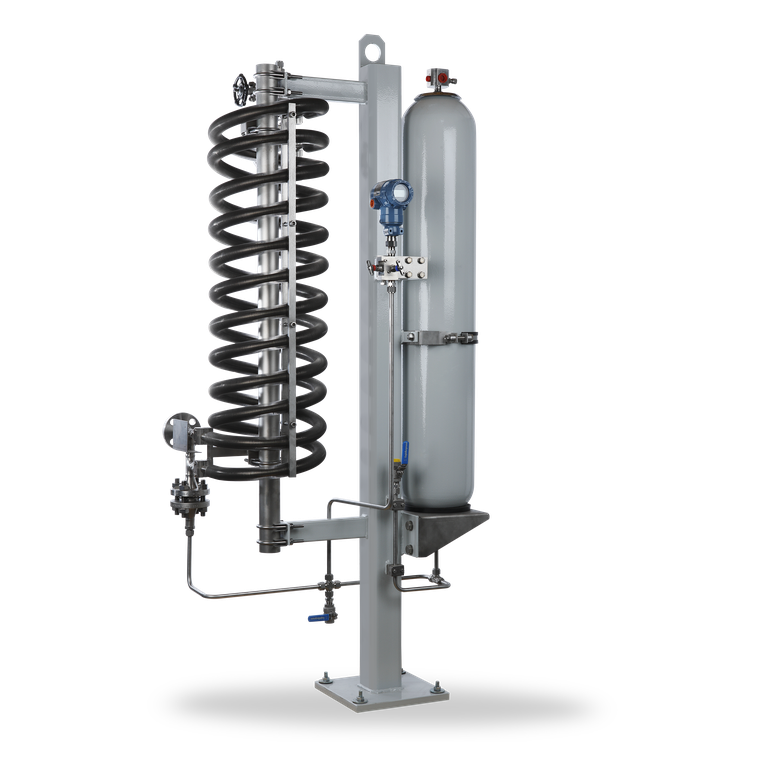

SPC6002A4 with air cooler

A From mechanical seal

B To mechanical seal

C Fill

G Vent

H Pressure reference

A From mechanical seal

B To mechanical seal

C Fill

G Vent

H Pressure reference

SPO (Plan 53C)

Features

Pressurized barrier system (closed circuit) for use in seal systems with high pressures and/or for hazardous/environmentally harmful processes. The SPO Plan 53C range is available with a pressure booster, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

Circulation in accordance with API 682 / ISO 21049: Plan 53C

Circulation in accordance with API 682 / ISO 21049: Plan 53C

Advantages

- Pressurization is by means of a pressure booster

- Automatic setting of the barrier pressure via reference pressure: simple and reliable mode of operation

- Safe operation even in case of pressure changes

- Barrier pressure is created without any need for connection to a nitrogen supply

- Available with finned tube, water or air coolers with fan

- Modular system: combination with a wide range of system components/instruments possible

Standards and approvals

- PED 2014/68/EU (Design and production in accordance with EU Pressure Equipment Directive)

- ASME VIII, Div. 1 (Design, calculation and production)

Recommended applications

- Petrochemical industry

- Chemical industry

- Oil and gas industry

- Refining technology

Functional description

The SPO is designed to perform the following functions of a barrier system:

Pressurization (> process pressure) prevents the process medium from getting into the barrier circuit or the atmosphere. Pressurization is supplied by a pressure booster in dependency on the process pressure. Circulation in the barrier circuit takes place by the thermosiphon principle or by forced circulation, e.g. with a pumping screw.

- to pressurize the buffer chamber

- leakage compensation

- to cool the seal

Pressurization (> process pressure) prevents the process medium from getting into the barrier circuit or the atmosphere. Pressurization is supplied by a pressure booster in dependency on the process pressure. Circulation in the barrier circuit takes place by the thermosiphon principle or by forced circulation, e.g. with a pumping screw.

Notes

A refilling unit has to be provided.

Product variants

| Designation | SPC6000A4 | SPC6001A4 | SPC6000A4 | SPC6001A4 | ||||

|---|---|---|---|---|---|---|---|---|

| Design code | ASME VIII, Div. 1 | PED 2014/68/EU | ASME VIII, Div. 1 | PED 2014/68/EU | ||||

| Type of heat exchanger | Air cooler a) |

Water cooler b) |

Air cooler a) |

Water cooler b) |

Air cooler a) | Water cooler b) |

Air cooler a) |

Water cooler b) |

| For shaft diameters ≤60 mm (acc. to API 682) |

■ | ■ | ||||||

| For shaft diameters >60 mm (acc. to API 682) |

■ | ■ | ||||||

| Piston accumulator (liters) | 2.8 | 2.8 | 5.1 | 5.1 | ||||

| Allowable pressure1) | 44 bar (638 PSI) | 44 bar (638 PSI) | 44 bar (638 PSI) | 44 bar (638 PSI) | ||||

| Allowable temperature – piston accumulator1) |

-20 °C … +90 °C (-4 °F … +194 °F) |

-20 °C … +90 °C (-4 °F … +194 °F) |

-20 °C … +90 °C (-4 °F … +194 °F) |

-20 °C … +90 °C (-4 °F … +194 °F) |

||||

| Allowable temperature – system1) |

-20 °C … +90 °C (-4 °F … +194 °F) |

-20 °C … +90 °C (-4 °F … +194 °F) |

-20 °C … +90 °C (-4 °F … +194 °F) |

-20 °C … +90 °C (-4 °F … +194 °F) |

||||

| Cooling capacity – with water cooled heat exchanger (kW)2) |

10 | 10 | 10 | 10 | ||||

| Cooling capacity – with air cooled heat exchanger (kW)2) |

2.0 | 2.0 | 2.0 | 2.0 | ||||

| Metal parts | 316/316L | 316/316L | 316/316L | 316/316L | ||||

Other versions and connections (flanged, threaded, welded) on request.

1) Design data, permissible working values depend on the actual conditions of service.

2) The cooling performance depends on the available fluids, their temperatures and flow rates. Please contact EagleBurgmann for professionally selecting the correct heat exchanger.

a) WEL6002A4

b) WEF6100A4

Similar products

NF-GO Supply System

With the new NF-GO seal supply system it is possible to supply barrier fluid to double and tandem mechanical seals for a broad range of applications. NF-GO systems are equipped as standard with all the necessary system connections and brackets. The system allows for multiple additional components for remote monitoring such as seal temperature monitoring with PT-100 sensors, pressure measurement and leakage detection by flow monitoring.

SPO (Plan 53B)

Pressurized barrier system (closed circuit) for use in seal systems with high pressures and/or for hazardous/environmentally harmful processes. The SPO (Plan 53B) range is available with a pressure accumulator, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

Circulation in accordance with API 682 / ISO 21049: Plan 53B

Circulation in accordance with API 682 / ISO 21049: Plan 53B