Espey WD200

Espey WD200

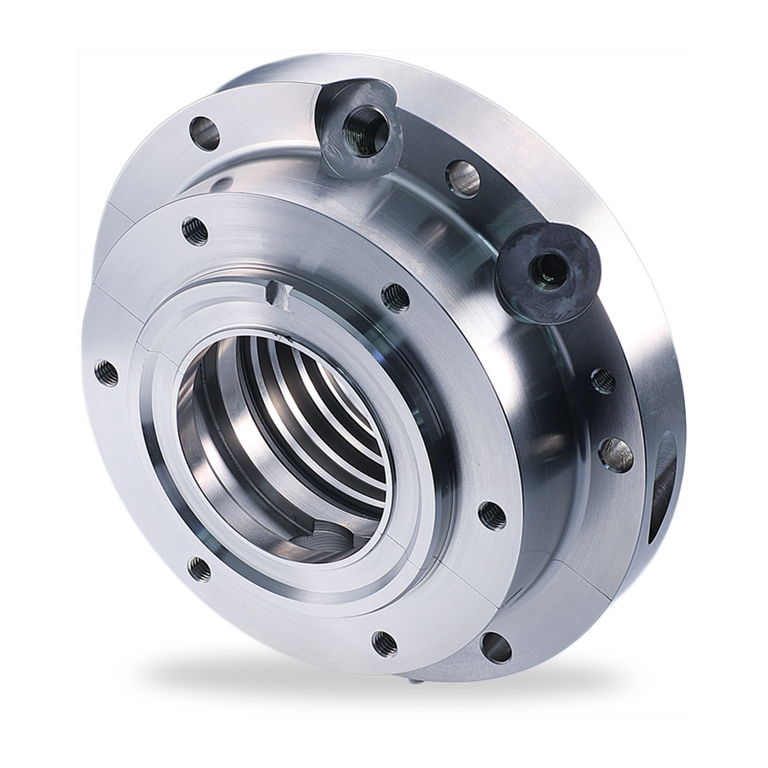

| Item | Description |

| 1 | Flat seal |

| 2 | Housing, 2-piece |

| 3 | Seal ring |

| 4 | Tension spring |

| 5 | Detent |

Espey WD200

Features

- Split housing design

- Multi-part seal rings, radially cut

- Very small operation gap - low leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free - sliding faces and machine consume no additional power

Advantages

- Easy installation by split housing design

(shaft removal not required) - Long-term operation time

- Maintainability

- Segmented seal rings for easy replacement

Materials

Seal ring: Carbon, PTFE compound

Housing: 1.4021, 1.4571, Hastelloy®, Titanium, Inconel®, others

Tension spring / detent: 1.4571, Hastelloy®, Titanium, Inconel®

Housing: 1.4021, 1.4571, Hastelloy®, Titanium, Inconel®, others

Tension spring / detent: 1.4571, Hastelloy®, Titanium, Inconel®

Standards and approvals

- FDA

- Compliant to TA Luft (German Clean Air Act)*

Recommended applications

- Chemical industry

- Waste incineration and removal industry

- Power plant technology

- Petrochemical industry

- Food processing industry

- Metal production and processing

- CO2 transportation and storage

- Gases

- Fumes and exhaust,solids containing, flammable (Atex), acid containing and toxic gases

- (Solids containing) steams / liquid mist

- Oil mist / penetrating oil

- Water

- Medium-sized and large fans / blowers

- Bearing seals (gear box, motors)

- Steam turbines

- Mixers, agitators, mills, dryer

Product variants

Espey WD200-WDK

with short design and grease barrier port - type WDKF in addition with reduced outside housing diameter (for clean media, not for solids containing gases).

with short design and grease barrier port - type WDKF in addition with reduced outside housing diameter (for clean media, not for solids containing gases).

Espey WD200-WDKF

with short design, reduced housing outside diameter and grease barrier port (for clean media, not for solids containing gases).

with short design, reduced housing outside diameter and grease barrier port (for clean media, not for solids containing gases).

For toxic and solids containing gases as well as Atex applications type shaft seal

Espey WD200-WDKS with short design, reduced housing outside diameter and barrier gas port (for e.g. toxic and solids containing gases as well as Atex applications, on special request).

Espey WD200-WDKS with short design, reduced housing outside diameter and barrier gas port (for e.g. toxic and solids containing gases as well as Atex applications, on special request).

Espey WD200-WDS

with barrier gas and grease barrier port (for e.g. toxic and solids containing gases as well as Atex applications, on special request).

with barrier gas and grease barrier port (for e.g. toxic and solids containing gases as well as Atex applications, on special request).

Espey WD200-WDA

for applications involving condensate formation to enable directed throwing off to the outside of the housing.

for applications involving condensate formation to enable directed throwing off to the outside of the housing.

Espey WD200-WDSA

with barrier gas, suction and grease barrier port (for e.g. toxic and solids containing gases with condensate formation as well as Atex applications).

with barrier gas, suction and grease barrier port (for e.g. toxic and solids containing gases with condensate formation as well as Atex applications).

Similar products

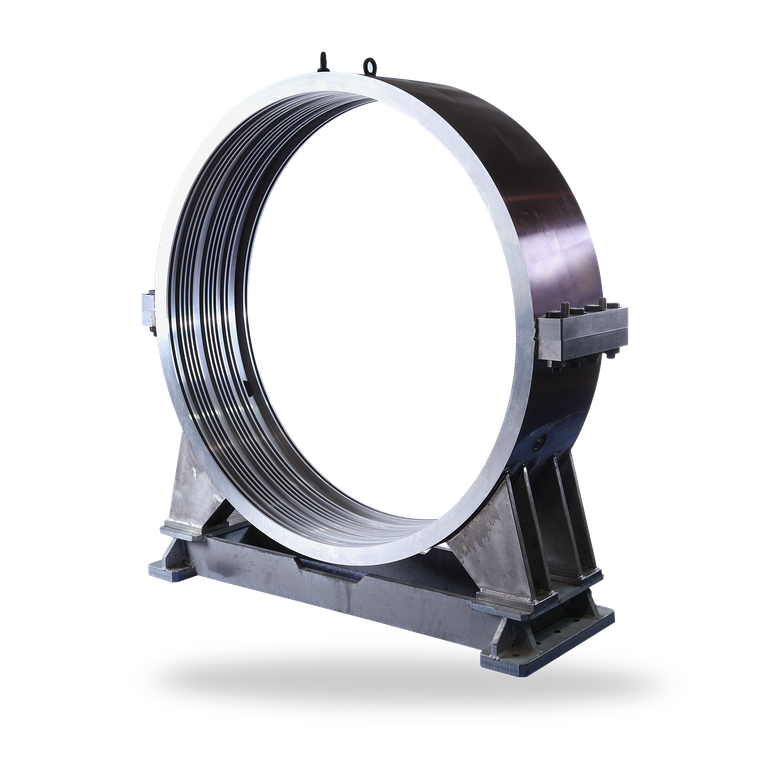

Espey Magna500+ the large seal for diameters from 500 mm

- Split housing design

- Segmented and self-adjusting seal rings

- Virtually maintenance- and wearfree

- Dry-running

- Suitable for horizontal and vertical use

Espey WD100

- Split housing design

- Multi-part seal rings, radially cut

- Very small operation gap – low leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free – sliding faces and machine consume no additional power

Espey WD200/500

- Multi-part seal rings, radially cut on process side, overlapped mortised with gas tight joints on atmosphere side (adjusting)

- Split housing design

- Lowest possible operation gap - lowest leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- Short axial installation length

- No sealing components mounted on the shaft and hence no additional shaft vibrations