EagleBurgmann international

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

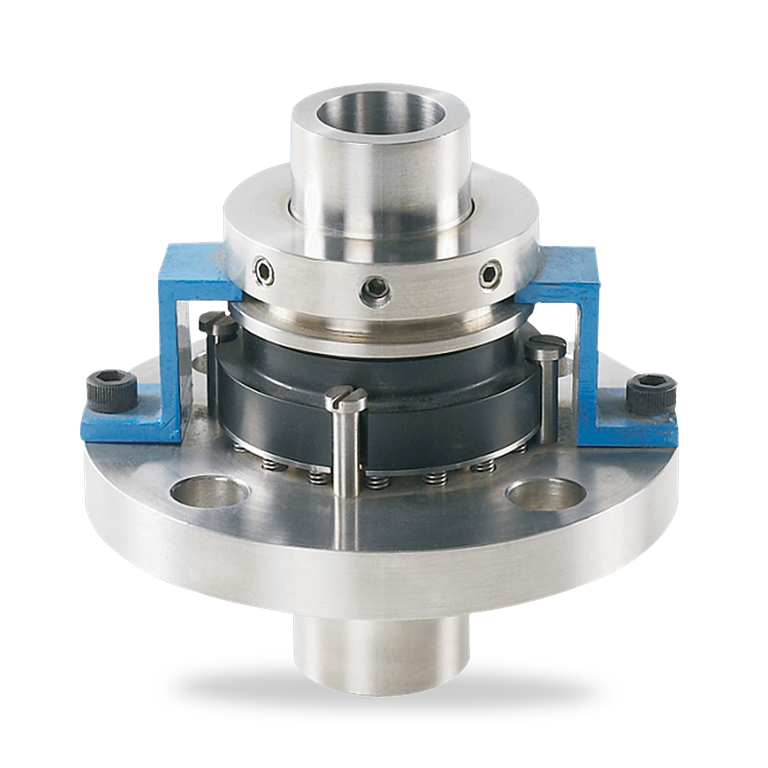

Dry running seal

AD5

Dry running seal

AD5

Features

- Rotating multi-spring pusher seal

- Balanced

- Independent of direction of rotation

- Special face material Teflon® eliminates the contamination of media

- Ideally suited for pharmaceutical and food industry

Advantages

- Over 35 years of running reference in the field

- Minimum seal face heat generation due to narrow seal cross section

- Very cost effective since lubrication/cooling system is not required

- Ease of installation and maintenance as simple in construction

- Minimise media contamination as seal is externally mounted

Operating range

Pressure: p = 5 torr ... 5 bar (0.1 ... 72 PSI)

Temperature:

t = -30 °C ... +175 °C (-22 °F ... +347 °F)

Sliding velocity: vg = 1 m/s (3.3 ft/s)

Axial movement: ±0.3 mm

(Consult EB for applications outside above limits).

Materials

Mating ring: Ceramic

Secondary seals: FKM, FFKM

Springs: Hastelloy® C-4

Metal parts: SS 316, other materials on request.

Recommended applications

- Process industry

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Power plant technology

- Water and waste water technology

- Building services industry

- Food and beverage industry

- Sugar industry

- Horizontal and vertical pumps, agitators, mixers

Recommended piping plans

Similar products

Dry running seals DR1, DR2

- Rotating multi-spring pusher seal

- Balanced

- Uniform seal face loading

- Special carbon material with dry running capability

- Single-outside mounted arrangement (DR1)

- Single and back-to-back arrangement (DR2)

Inquire about individual solutions

We develop and produce customer-specific special and individual solutions for every application.

The Eagleburgmann Group

Sealing technology for plants and machines

EagleBurgmann is one of the worldwide leading providers of industrial sealing technology. Mechanical seals, seal supply systems, magnetic couplings, carbon floating ring seals, expansion joints, gaskets and packings as well as comprehensive services are used wherever reliability and safety are needed.

Mechanical seals and more

Sealing technology by EagleBurgmann is used worldwide in oil and gas industries, refineries, the petrochemical, chemical, and pharmaceutical industries, food processing, energy, water, mining, paper, aerospace, and other industries. Close to 5,800 employees provide their ideas, solutions, and commitment so that customers can rely on our sealing technology.

What makes us stand out is our excellent quality, great innovative capacity, and an extensive product portfolio for nearly all industrial processes and fields of application. Our product portfolio includes everything from mechanical seals and seal supply systems to magnetic couplings, carbon floating ring seals, expansion joints, and gaskets and packings as well as comprehensive services. Since we are part of the German Freudenberg and Japanese EKK group, we have all the necessary resources for a firmly based reliable partnership.