Burajet Chamber rings

8032/AU

Burajet Chamber rings

8032/AU

Burajet Chamber rings

8032/AU

Features

Burajet retainer rings are molded HPU (hydrolysis-resistant polyurethane) or FKM (fluorocarbon rubber) rings with sealing lip which are produced to match the shaft and gland housing. They efficiently retain the Burajet injectable compound packings, thus reducing product contamination. The compensation for radial shaft movements is also better than with braided packings.

Advantages

- Easy to handle during installation.

Recommended applications

Industries

- Process industry

- Chemical industry

- Pulp and paper industry

- Water and waste water technology

- Mining industry

- Sugar industry

- Building services industry

- Pumps

- Mixer

- Kneaders

- Agitators

- Refiners

- Valves

Notes

Easy to handle during installation. To make it easier to fit into assembled systems, the profile ring can be cut through at one point and then glued back together using cyanoacrylate adhesive. The rings are manufactured to fit the shaft and gland housing diameters. An exact measurement is needed (accurate to 0.1 mm) in order to produce the lip seals with the correct dimensions.

Forms of supply

- Custom-made retainer rings

- Made to order

- 2 rings per set

Similar products

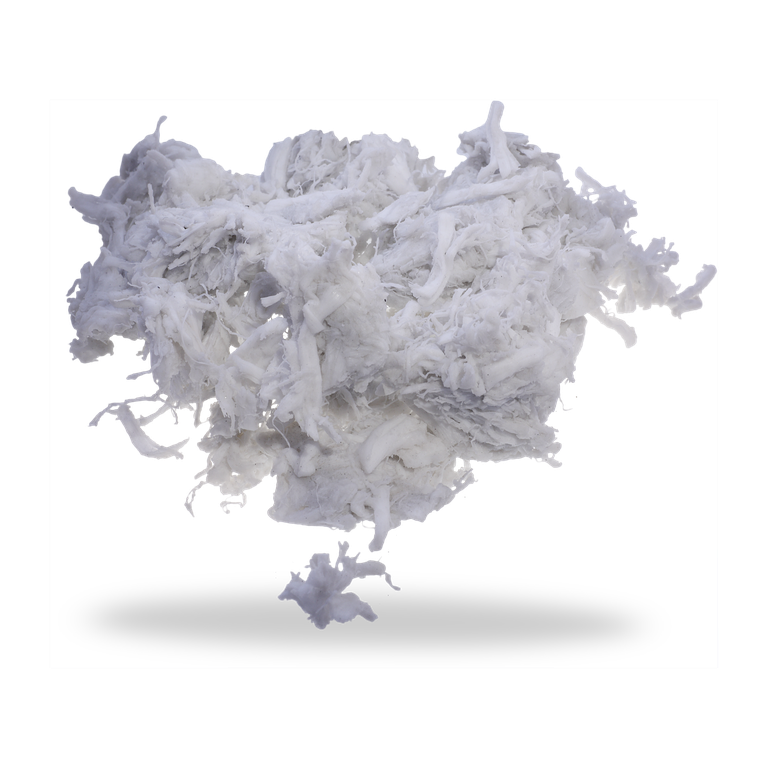

Burajet SCW 8032/SCW

Burajet SCW 8032/SCW is a fiber injectable packing based on PTFE fiber with a heavy-duty lubricant. For some applications, it may be necessary to retain it between braided compression packings (e.g. Burasoft L 6225/L or Buramex 6335). To reduce product contamination and to compensate better for radial shaft movements, a special retention between HPU (hydrolysis-resistant polyurethane) or FKM (fluorocarbon rubber) lipped rings is used.

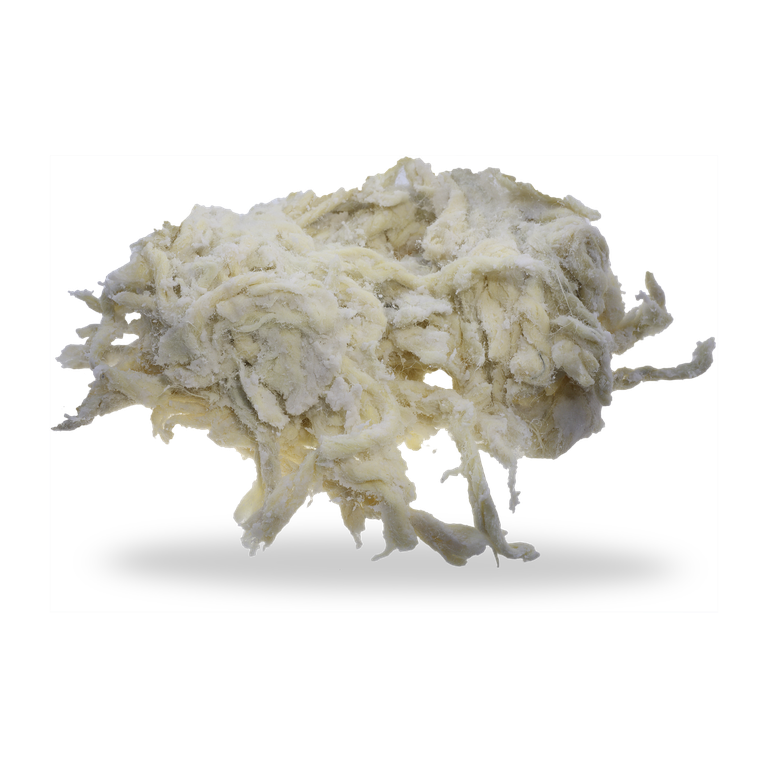

Burajet SCA 8032/SCA

Burajet SCA 8032/SCA is a fiber injectable compound based on aramid/PTFE with a special lubricant. For some applications, it may be necessary to retain it between braided compression packings (e.g. Buramex SF 6335 or Araflon 6426).

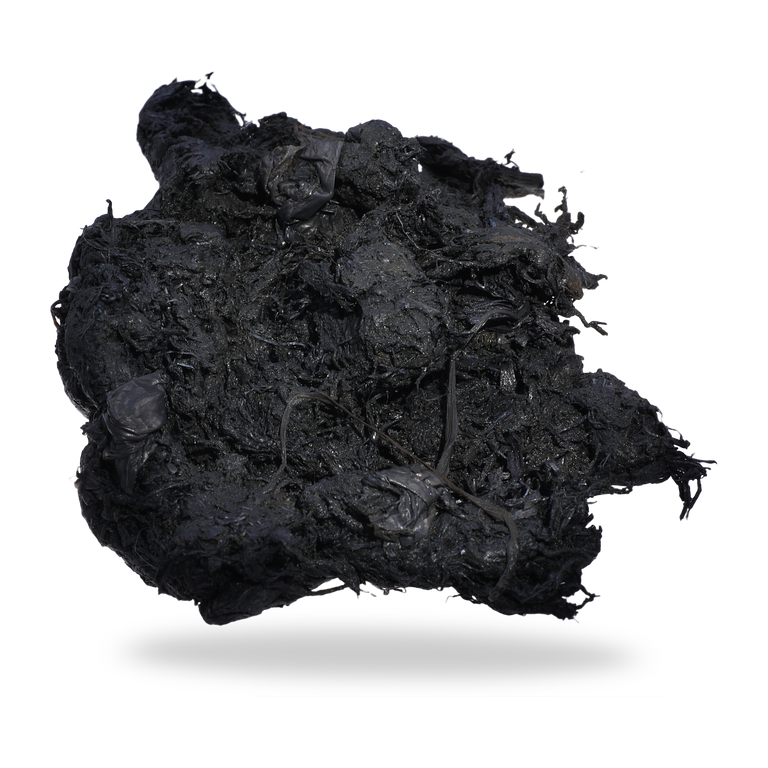

Burajet SCB 8032/SCB

Burajet SCB 8032/SCB is a fiber injectable packing based on PTFE fiber with a graphite-based heavy-duty lubricant. For some applications, it may be necessary to retain it between braided compression packings (e.g. Buraflex 2000/HT). To reduce product contamination and to compensate better for radial shaft movements, a special retention between HPU (hydrolysis-resistant polyurethane) or FKM (fluorocarbon rubber) lipped rings is used. The packing is used in almost all branches of industry.